Chapter 11 Chapter 3: The Lighting Industry That Lights Up Life

The history of the lighting industry is divided into three stages by representative technology.Figure 3-1 shows the products of different eras from left to right, representing three eras, namely, the era of filament bulbs (incandescent lamps), the era of gas bulbs (fluorescent lamps), and the era of semiconductor lighting (LEDs), among which the era with the longest history The incandescent lamps and future mainstream LEDs are the most important focus of investigation.

Our research found that, regardless of the technology of the era, the industrial chain of the lighting industry is surprisingly similar.Next, we will introduce the LED industry chain by comparing old-fashioned light bulbs.

Figure 3-1 History of Lighting Technology

1. Bulb production process - five-step process

The production of a typical tungsten filament bulb product requires the following five steps:

(1) Production of tungsten materials

Materials are the foundation of everything.The tungsten material for lighting is a kind of tungsten alloy, and the ratio of its various elements greatly affects the luminous efficiency of tungsten.Edison's greatest contribution was to find the most suitable luminescent material under the circumstances at that time.

(2) Extraction of tungsten wire

Morphology is necessary to maximize efficiency.Tungsten wire is made by changing the shape of tungsten material, and after hundreds of years of practice, the shape of the filament has finally formed the current convoluted shape, as shown in Figure 3-2.If it is too thin, it is easy to burn, and if it is too thick, the luminous intensity will not be enough and the cost will be high.In the industry standard of light bulbs, the filament part is the most regulated part.

(3) Add lamp holder

Cars without wheels, horses without saddles, and soldiers without guns, how can they surrender to the commander?As the power supply equipment of the light bulb, the lamp holder is a very important part. The metal part under Figure 3-3 is the light bulb holder.

(4) add light bulb

Because the bulb is a vacuum, the heating filament is not oxidized.The degree of vacuum determines the life of the bulb.Figure 3-4 is our common incandescent bulb.In Cantonese, people who get in the way between lovers are called "light bulbs" because the bulbs are "not ventilated".

(5) Bulb application

The product that ultimately determines the lighting is how to use the light bulb. For example, the desk lamp in Figure 3-5 is a product that adds other components to bring lighting to the desk.

Morphology is necessary to maximize efficiency.Tungsten wire is made by changing the shape of tungsten material, and after hundreds of years of practice, the shape of the filament has finally formed the current convoluted shape, as shown in Figure 3-2.If it is too thin, it is easy to burn, and if it is too thick, the luminous intensity will not be enough and the cost will be high.In the industry standard of light bulbs, the filament part is the most regulated part.

(3) Add lamp holder

Cars without wheels, horses without saddles, and soldiers without guns, how can they surrender to the commander?As the power supply equipment of the light bulb, the lamp holder is a very important part. The metal part under Figure 3-3 is the light bulb holder.

(4) add light bulb

Because the bulb is a vacuum, the heating filament is not oxidized.The degree of vacuum determines the life of the bulb.Figure 3-4 is our common incandescent bulb.In Cantonese, people who get in the way between lovers are called "light bulbs" because the bulbs are "not ventilated".

(5) Bulb application

The product that ultimately determines the lighting is how to use the light bulb. For example, the desk lamp in Figure 3-5 is a product that adds other components to bring lighting to the desk.

2. LED production process - the same five-step process

Similar to the five steps of the light bulb above, the LED lighting process can also be divided into similar processes.

(1) Generation of epitaxial wafers - materials

Just as tungsten alloy is the basis of a light bulb, a composite material called an epitaxial sheet (Epitaxi.al Slice) is the luminous core of an LED.The principle of traditional lighting is to convert heat energy into light energy through metal heating, and the conversion efficiency is very low, only about 7%.The light emitting principle of LED is very different. When electrons pass through a layer of semiconductor material, the semiconductor material is excited to convert electrical energy into light energy, so it can directly emit light without heating. At present, LED can convert 40% of electrical energy into light energy. .With the advancement of technology, the conversion rate will become higher and higher, which may reach 70% in theory.This is a qualitative leap in the history of lighting, and such an excellent energy-saving effect also makes it a major factor in the mainstream of lighting in the future.

However, the light-emitting ability of single-layer semiconductors is very weak, so epitaxial wafers are superimposed with many layers of very thin single-layer materials and pressed into composite materials like puff pastry, as shown in Figure 3-6.Therefore, the luminous efficiency of LED depends on how many layers can be pressed into the same thickness.The thinner the single-layer material can be made, the more layers can be stacked, and the higher the luminous efficiency.Now, the thickness of each layer is generally only 2~20 microns. This production technology requirement also determines that the production of epitaxial wafers is the most difficult part of the entire LED production process. At present, it is generally through a metal organic chemical vapor deposition system (MOCVD) technology for synthesis.

2. LED production process - the same five-step process

Similar to the five steps of the light bulb above, the LED lighting process can also be divided into similar processes.

(1) Generation of epitaxial wafers - materials

Just as tungsten alloy is the basis of a light bulb, a composite material called an epitaxial sheet (Epitaxi.al Slice) is the luminous core of an LED.The principle of traditional lighting is to convert heat energy into light energy through metal heating, and the conversion efficiency is very low, only about 7%.The light emitting principle of LED is very different. When electrons pass through a layer of semiconductor material, the semiconductor material is excited to convert electrical energy into light energy, so it can directly emit light without heating. At present, LED can convert 40% of electrical energy into light energy. .With the advancement of technology, the conversion rate will become higher and higher, which may reach 70% in theory.This is a qualitative leap in the history of lighting, and such an excellent energy-saving effect also makes it a major factor in the mainstream of lighting in the future.

However, the light-emitting ability of single-layer semiconductors is very weak, so epitaxial wafers are superimposed with many layers of very thin single-layer materials and pressed into composite materials like puff pastry, as shown in Figure 3-6.Therefore, the luminous efficiency of LED depends on how many layers can be pressed into the same thickness.The thinner the single-layer material can be made, the more layers can be stacked, and the higher the luminous efficiency.Now, the thickness of each layer is generally only 2~20 microns. This production technology requirement also determines that the production of epitaxial wafers is the most difficult part of the entire LED production process. At present, it is generally through a metal organic chemical vapor deposition system (MOCVD) technology for synthesis.

Figure 3-6 Epitaxial wafer generation

Metal-organic chemical vapor deposition system technology, which is a chemical vapor deposition (CVD) process that uses metal-organic compounds as source materials. The most attractive aspect of MOCVD technology is its versatility, as long as a suitable metal-organic source can be selected, epitaxial growth can be performed.Generally, the MOCVD growth process can be described as follows: the reaction source material (granular metal material) whose flow rate is precisely controlled is carried by a carrier gas (usually H2, and some systems use N2) into a quartz or stainless steel reaction chamber, Reactive precipitation occurs on the substrate, and a thin layer of epitaxial layer is uniformly grown, and the substrate is placed on a pedestal with controlled temperature.The tail gas remaining after the reaction is swept out of the reaction chamber. The working principle of MOCVD is shown in Figure 3-7.

Figure 3-7 MOCVD working principle

(2) Cutting - LED Core

It is equivalent to pulling out the filament from the tungsten material, as shown in Figure 3-8, different from the curved filament, the epitaxial wafer after cutting is square.Due to the special structure of the epitaxial wafer, it is very difficult to cut out the required light-emitting core without damage.Not only a vacuum environment is required, but also a professional cutting machine.At present, there are only two manufacturers producing this special cutting machine in the world.

Figure 3-8 Epitaxial Wafer Cutting

(3) Core - put in the LED chip

The chip is to the LED, just like the lamp holder is to the light bulb, it is the power supply part.The chip is a very important equipment to realize the ideal LED, because the LED has a very high requirement for current.Figure 3-9 is a schematic diagram of the completed LED chip.

(4) Encapsulation - LED chips into illuminants

Encapsulating LED chips into a luminous body is like adding a lampshade to a filament lamp holder to make a light bulb.The shape of the lampshade can be different according to the needs, but the technology of packaging determines the service life of this luminous body.The LED chip in Figure 3-10 is packaged in a square lampshade.

(5) Lighting application

That's how to apply LED illuminants.Just like applying incandescent light bulbs, assemble products according to different functions and needs.Figure 3-11 is an example of a product after assembling the LED illuminant.

(5) Lighting application

That's how to apply LED illuminants.Just like applying incandescent light bulbs, assemble products according to different functions and needs.Figure 3-11 is an example of a product after assembling the LED illuminant.

Figure 3-11 LED application

3. Summary of this section

In the same five-step process, we found that, like light bulbs, for LED lighting, the first to third steps - epitaxial wafers, dicing and LED chips are upstream, the fourth step - packaging is midstream, and the fifth step - the application is downstream.Upstream accounts for 70% of the overall profit, and is strictly controlled by the top five foreign manufacturers, who own 85% to 90% of related patents.What Chinese local companies do most is the most downstream packaging and application.After understanding the process flow and the distribution of successful enterprises in the industrial chain, we understand that the nature of the industry and the positioning of the industry are closely related.

As a technology-oriented industry, we struggled with the large number of patents owned by each vendor during the research process.However, they have successes and failures, so it is not technology or patents that determine everything, but how to maximize the utility of technology is the ultimate proposition of success.We found that all successful lighting companies, whether they are the traditional lighting giants or emerging LED companies, have one thing in common, that is, they use different methods to try to achieve a balance between centralization and decentralization. The following figure 3-12 is a simple explain what they have in common.Unsuccessful companies, such as Sumitomo or Taiwan’s packaging industry mentioned below, have their own technologies, but because they do not balance centralization and decentralization, do not make full use of technology, and do not grasp the industry’s essence of maximizing the utility of technology, they all have their own technologies. was defeated.

Figure 3-12 Industry essence

1. What is centralization

In short, it is to build technical barriers to limit competition and increase their profit margins.We have seen that after entering the era of LED lighting, a large number of infringement lawsuits have emerged in an endless stream.On the other hand, major manufacturers in the industry tend to form offensive and defensive alliances, exchange patents to form a patent pool, control technology patents in an all-round way, and work together to squeeze the entry of new competitors.Figure 3-13 is a simple schematic diagram of centralization. The double arrows in the gray circle represent technology exchanges between major manufacturers, and the industry barriers represented by cylinders in the figure are constructed through cross-authorization.

Figure 3-13 Schematic diagram of centralization

2. What is decentralization

It is not enough to have profit margins alone. Only by expanding the market capacity can a large amount of profits be obtained.During the research process, we found a major feature, that is, a large number of cross-licensing or franchise licensing among manufacturers.This kind of decentralization action expands the influence of the technology in your hands, so that you can become the mainstream of the industry in the future, and you can be at the core of the industry.Figure 3-14 is a simplified schematic diagram of decentralization. The black arrows indicate that the core manufacturers license patents downwards, thus gaining a broader market represented by the gray dotted circles.

Figure 3-14 Schematic diagram of decentralization

In practice, in order to grasp the industry essence of decentralization and centralization to maximize the technical utility according to the time and local conditions, it is necessary to analyze the specific situation of each enterprise in combination with its own industry position.

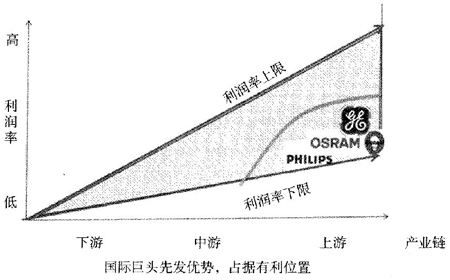

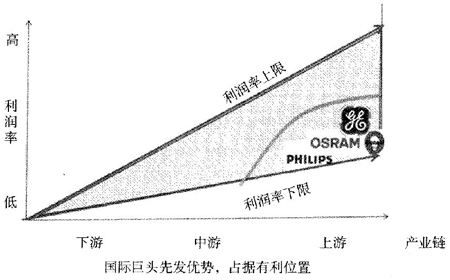

Figure 3-15 Profit margin

The grasp of the nature of the industry has led to different positioning of lighting companies. Below we use a picture to explain the industry positioning of each lighting company.In Figure 3-16, the horizontal axis from left to right represents the lower, middle and upper reaches of the industrial chain, and the vertical axis from bottom to top represents the change in profit margins from low to high.The two rays clearly plan the upper and lower limits of profit margins for the upper, middle and lower reaches of the industrial chain. It can be clearly seen that the closer to the upstream of the industrial chain, the greater the profit margin of the enterprise.Finally, the triangle formed in Figure 3-16 is used to define the entire lighting industry.

Figure 3-16 Three giants seize the core

Since the end of the 19th century, international lighting giants represented by Philips, Osram and General Electric have preemptively occupied the core interest circle in the middle and upper reaches of the industrial chain through advanced technology and strong financial resources, that is, the arc in Figure 3-16.

Figure 3-17 briefly summarizes the general distribution of different companies in the industry at present. For more than 100 years, international giants have maximized the utility of technology through decentralization and centralization of power, thus successfully expanding their territory and occupying most of the mid-upstream market space.However, the giants chose the high-margin market, and did not strive to cover everything. There are gaps in the market segment with low profit margins in the downstream of the industrial chain. It is at this time that Chinese companies enter the downstream market abandoned by the giants.And every technological innovation has factors that are difficult to predict and control, so the upstream will also leave a gap for emerging technology companies.

Figure 3-17 Decentralization to expand the profit zone

In the early 1990s, emerging companies represented by CREE in the United States and Nichia in Japan used revolutionary technology as a stepping stone to gain a place in the upper reaches of the industrial chain.As shown in Figure 3-18, then try to suppress the giants through technological centralization, and enter the inner circle from top to bottom.

Figure 3-18 Emerging companies from top to bottom

During the same period, Chinese companies lacking technology joined in, but had to compete in the market segment downstream of the industrial chain, which is the shaded area shown in Figure 3-19.There are also some well-known companies among them, such as Opple and NVC. The two companies have adopted similar strategies to make their fortunes. First, they must accurately position themselves in a certain market segment, and then vigorously develop sales channels and establish brands, so as to gain profits. market.But the problem is that the channel can be obtained by spending money to poach people, and the business model is easily copied by others and becomes invalid.Therefore, market means are not hard goods that are tightly held in the hands, and naturally there is no such thing as the essence of centralization and decentralization.Therefore, after Chinese enterprises have just left the rush period of the building materials market, they are now facing the confusion of being unable to break through again.

Figure 3-19 Chinese companies hovering downstream

In the industry distribution map, the more successful companies are, the deeper they go into the core area of profit, and the core area is surrounded by technical barriers between core manufacturers.In order to advance towards this goal, enterprises with different initial positioning try to use the technology in their hands as a stepping stone, and then cut into the core interest circle and expand the profit area occupied by them through the means of centralization and decentralization, that is, the pursuit of technological utility maximize.Below, we explain this process in detail one by one.

Figure 3-1 History of Lighting Technology

Figure 3-6 Epitaxial wafer generation

Figure 3-7 MOCVD working principle

Figure 3-8 Epitaxial Wafer Cutting

Figure 3-11 LED application

Figure 3-12 Industry essence

Figure 3-13 Schematic diagram of centralization

Figure 3-14 Schematic diagram of decentralization

Figure 3-15 Profit margin

Figure 3-16 Three giants seize the core

Figure 3-17 Decentralization to expand the profit zone

Figure 3-18 Emerging companies from top to bottom

Figure 3-19 Chinese companies hovering downstream