Chapter 12 Section Two

The three giants in the traditional lighting industry—Philips, GE, and Osram—all have a century-old history of fortune. Looking through the old calendars of these companies, we can see how they gained their core positions today by grasping the essence of the industry.

1. GE: Take a light bulb and invent an industry

(1) Edison: A successful man standing on the shoulders of giants

In the history of lighting development, the most critical turning point is undoubtedly the evolution from kerosene lamps to incandescent lamps.At the same time, everyone must have deeply remembered a great name, Edison, the father of GE, and the true and false legends behind him.Years engraved his name on the historical monument, but quietly buried other great men who made great contributions to the lighting revolution.The following is an incomplete history of the invention of the light bulb. It is found that Edison, the king of inventions, sometimes acted on the basis of "bringing doctrine".

(2) History of Lighting Development

In 1801, the British chemist Davy energized platinum wire to emit light.

In 1854, the American Henry Goebbels used a carbonized bamboo wire and placed it under a vacuum glass bottle to emit electricity.His invention appears today to be the first practical incandescent light bulb.The light bulb he tested at that time could last for 400 hours, but he did not apply for a design patent in time.

In 1850, the British Joseph Wilson Swan began to study electric lights. In 1878, he obtained a British patent for a light bulb powered by carbon filaments under vacuum, and began to establish a company in the UK to install electric lights in various homes.

In 1874, two electrical technicians in Canada applied for a patent for an electric light.They filled the glass bubble with nitrogen gas and glowed with an electrified carbon rod.But they did not have enough money to continue to develop the invention, so they sold the patent to Edison in 1875.

In 1875, after Edison bought the patent, he tried to improve the filament used. In 1879, he changed to carbon filaments to make light bulbs, which successfully lasted for 13 hours.By 1880, the carbonized bamboo filament light bulb he created had successfully maintained 1200 hours in the laboratory.

(3) Master advanced technology to lead the industry

Edison's technological success may have stood on the shoulders of giants, as Newton said.However, his commercial success comes from his advanced business philosophy of technology industrialization.He did two very correct things. The first one was the first to apply for the patent for the light source of the incandescent lamp; the second and more important thing was to successively invent the supporting appliances needed for lighting, such as generators, wires, switches, etc. , and applied for patents one by one.To control the upstream and downstream supporting products is to control the entire industrial chain and have the ability to centralize power, just like the bundled sales of software that Weiqin is facing today has reached the monopoly of application software.Later, Edison authorized carbon filament bulbs to be used by other manufacturers, setting the mainstream standard for bulbs at that time.Edison's two moves quickly industrialized electric lights and laid the foundation for him to establish the Edison Electric Company, the predecessor of GE.The first-mover advantages accumulated by Edison's successful centralization more than 200 years ago still benefit this long-established company today.

2. OSRAM: a name with connotation, an open vision

GE's focus on light source technology is by no means an isolated phenomenon. As the other two giants in the lighting industry, Osram and Philips, they also have a century-old foundation and a family history. At the Paris Electricity Exposition in 1881, the German Ratheno bought all the invention patents of Edison and founded the German Edison Applied Electric Company, the predecessor of Osram.Rathenor has done a more thorough job than his predecessors on the "Borrowing Doctrine", even taking his name from the beginning.

How did OSRAM get its name? In 1906, Osram improved the light source and replaced the carbon filament with metal osmium-tungsten alloy filament, and the luminous intensity far exceeded that of carbon filament.The German Edison Electric Company launched the Osram brand, and finally merged and integrated into the now familiar Osram.In German and English, OSRAM is not a word.At that time, the two filament metal materials of incandescent light bulbs-osmium and tungsten, they combined the "OS" of osmium (Osmium) in German with the "RAM" of tin (Wolfram) to become "OSRAM".Osram just represents the two light source metal materials used to make the filaments of incandescent bulbs.

Osram not only focuses on the control of light source technology, but also has an open vision. In the new LED lighting era, Osram is the most active manufacturer of outsourcing and authorizing LED production to the midstream and downstream. Almost half of Taiwanese companies are serving Osram. of.In this way, it not only increases the share of OSRAM technology in LED, but also enables OSRAM to focus on further research and development of light sources.

3. Philips: light source collector

(1) We have a light source for every application

Philips' history can be traced back to 1891, when Dutch mechanical engineers started producing carbon filament light sources in a former buckskin factory in Eindhoven, the Netherlands. 1908 was the first year Philips entered the world market and began to produce metal tungsten filament bulbs. The tungsten-filament gas-filled "half-watt" lamp hit the market in 1913, followed by the smaller "Arga" light source in 1915, when Philips' slogan was "We have a light source for every application" and began to take care of itself product patents.Philips Lighting currently has about 75,000 patents, 22,000 registered trademarks and 6,000 registered designs, more than all other competitors combined.As can be seen from Figure 3-20, in the total revenue, light source lighting devices contributed 51% of the sales.

(2) Technology-oriented acquisitions in the new century

Since the new century, facing a large number of new lighting technologies, Philips has acquired control of promising technologies through acquisitions.Below are some of the larger acquisitions.

In 2006, it acquired Lumileds, an American lighting technology company, for US$1.5 billion.

In 2007, it acquired ColorKinetics, an American professional LED manufacturer, for 592 million euros.

In 2007, acquired LTI, an American company with a patented high-intensity xenon lamp.

In 2009, it acquired Genlyte, an American lighting equipment manufacturer.

Figure 3-20 Revenue sources of Philips

4. Summary

From this, it is not difficult to find that the three giants in the traditional lighting industry today have firmly grasped the most advanced light source technology at that time. As long as there is a feasible technology at that time, they can be industrialized immediately, and they can succeed through simple technological leadership.Therefore, it can gain a three-point advantage in the era of electrification.But times have changed. In today's information age, the speed of technology dissemination is unimaginable before, and there will never be a situation like before.In the tide of the new lighting revolution, is it possible to be proud of the world just by mastering the advantages of light source technology?

Nichia Chemicals, 20 years ago was still a little-known small Japanese factory.No one expected that a lighting technology that was considered impossible in the 20th century was born in this company with more than 600 employees.Facing the situation where the traditional lighting giants are divided into three parts of the world, Nichia broke through the blockade of the giants and became the core of today's LED industry from being a vassal of others in the past.

1. Industry positioning - located in the most upstream technology gap of the industry chain

In our positioning map, Nichia, which mainly produces LED chips, is currently located in the upstream area of the industrial chain, and is gradually breaking through the core circle built by traditional lighting giants from top to bottom.From the official production of blue LED in 1994 to the expiration of its patent protection in 2010, Nichia's total sales will reach 1.2086 billion yen (about 10.987 billion U.S. dollars), and the pre-tax profit rate will reach as high as 50%.According to the report of IMS Research, a British market research company, in terms of the total revenue of LED packaging products in 2007, Nichia ranked first with a global market share of 24%.How Nichia has jumped from an unknown factory to an industry leader in just a few years, we will analyze in detail the road to success of the new champion in the following section.

2. Nichia’s Road to Success——Ten Years of Dormancy, Soaring to the Sky

(1) Dormant——OEM phosphor for GE

It is said that "ten years of dormancy, soaring into the sky".Nichia has spent 27 years, not only becoming a blockbuster, but also firmly sitting on the leading position in the emerging LED industry since then.Founded in 1956, Nichia Chemical Industry Co., Ltd. initially focused on the production of high-purity calcium salt products. In 1966, it began to manufacture phosphor powder for fluorescent lamps, and obtained GE's patent authorization for phosphor powder manufacturing. Since then, it has embarked on the road of exploration in the lighting industry.For a long time thereafter, Nichia was only one of many factories attached to lighting giants, and did not have the ability to master cutting-edge lighting technologies. In 1980, the GE patent licensing contract ended.Nichia established a research institute in 1986 and began to devote itself to the research of luminescent substances.However, thanks to GE's patent authorization for many years, Nichia has accumulated a certain amount of technology in the journey of exploring new light-emitting technologies.

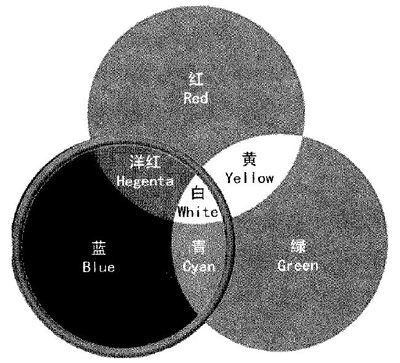

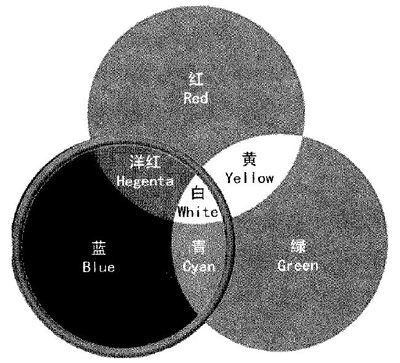

(2) Awakening of Insects - Unconventional way brings LED breakthrough

In 1993, Nichia took the lead in the world's LED industry with the invention of blue LED by Shuji Nakamura.What exactly is the technology that makes a little-known start-up company famous?It turns out that as early as the 1960s, GE developed the first visible red LED and made it widely used as an indicator light source for instruments and meters.After nearly 30 years of technological development, people have gradually developed red LEDs and green LEDs with higher brightness, but the three primary colors lack blue light sources.Figure 3-21 shows the principle of simple three-primary color formation, all primary colors are needed to synthesize white.Therefore, only when blue is invented, LED can produce white light, thus entering the general lighting market.The blue light source not only represents higher brightness LED technology, but also draws a broader market for LED technology.At that time, the world's lighting giants vigorously promoted fluorescent lamps to become the mainstream lighting products, and even Texas Instruments, which made a fortune in making precision instruments, gave up investment in LED research.However, Nichia did not rely on its old business of making phosphors. It followed the trend and chose the fluorescent lamp technology that was gradually dominating the market at that time, but chose a tortuous and legendary road.A technology that is world-renowned and recorded in the annals of history was born in an inconspicuous "small workshop", leading a new direction for the development of the entire lighting industry and triggering a new revolution.It all stems from the legendary Shuji Nakamura.

(3) Betting on LEDs - seeking breakthroughs in non-mainstream technologies

Back then, Shuji Nakamura was just a technical researcher in a factory. In order to seek a breakthrough in his career, Nakamura chose blue LEDs, which the entire industry was helpless at the time.When the research was started in 1989, two materials, zinc selenide (ZnSe) and gallium nitride (GaN), were considered to be used to make blue LEDs, and the mainstream at that time was zinc selenide.There are more than 10,000 researchers working on zinc selenide all over the world, but less than 10 people study gallium nitride, because high-quality gallium nitride crystals are difficult to obtain.Shuji Nakamura, who relied on his own strength at that time, had successfully developed new businesses for the company, but was not reused by the company due to the small sales volume.So Shuji Nakamura chose gallium nitride as the research target. Once successfully developed, it will form a large-scale business, thereby improving the treatment in the company.But the real situation is still grim, because there is no budget, so it is impossible to purchase related equipment and expensive components.As a result, it was only possible to manufacture the relevant equipment entirely on its own.Due to the uncertain future, Nichia even ordered the suspension of research.It is the persistence of the modern version of "Edison" that led to the original invention. It can be said that Shuji Nakamura relied on his own strength to fight tenaciously on the blue LED road that is difficult to predict the future.Four years later, in 1993, blue LEDs were introduced.Nichia became the first company in the world to produce blue LEDs. Surprisingly, it was not a well-known university at home or abroad who had been engaged in research in this field for a long time, nor was it a large electronics manufacturer, but a company in a local city. chemical manufacturers.From only $20 million in annual revenue to billions of dollars now.Nichia is a well-deserved leader in today's LED lighting industry, and has undoubtedly written a legendary and inspirational history for latecomers.Shuji Nakamura is nothing more than a godsend opportunity for Nichia, and how he can seize the opportunity to become a leader in the industry is also worth thinking about.

Figure 3-21 Principles of three primary colors

3. Maximization of technical utility - a game of centralization and decentralization

First of all, firmly control advanced technology and dominate the land of patent strategists.According to the "Applicant Score Ranking" of the World Intellectual Property Bank, Nichia's LED lighting technology competitiveness has always ranked first in the world.Nichia is undoubtedly the company with the most LED patents. Only before 2002, Nichia obtained 74 basic patents from LED epitaxy and chip to packaging manufacturing from 1991 to 2001, covering almost the entire process of technology and Relevant raw materials have an absolute monopoly in the LED field.It is precisely because of the core technology that Nichia can take the initiative to attack opponents on a global scale and hold technological power in its hands.

Frustrated monopoly technology, trying to solve the problem by launching a global patent litigation battle.First of all, Shuji Nakamura, a founding hero who was dissatisfied with Nichia's treatment of technical personnel and left, filed a lawsuit on the grounds of allegedly leaking corporate secrets.Instead, Nakamura Shuji filed a lawsuit that the patent right does not belong to the right confirmation of service invention.If the lawsuit is successful, Nichia's long-guarded leadership will be fundamentally shaken.

At the same time, due to the importance of this invention, it is considered as a basic invention that can compete for the Nobel Prize in the academic circle, and the global competition is very fierce.Table 3-1 is the preliminary statistics of global LED patent litigation as of the beginning of 2009, with a total of 59 cases.It can be seen from the collation that the patent lawsuits initiated by Nichia Chemicals account for almost 60% of all lawsuits in the world!While fighting with domestic rival Toyoda Gosei, Nichia is also fighting with Seoul Semiconductor in South Korea and CREE in the United States. 2001 was a bad year for Nichia. Before 2000, Nichia's patent litigation was basically invincible, but since 2001, Nichia has suffered a series of setbacks in patent litigation.The aggressive Nichia tried to monopolize the technology to lead the LED industry at all costs, and resolutely refused to open or authorize the patent to any other manufacturers.

Data source: Sci-Tech Policy Research and Information Center - Science and Technology Industry Information Office, 2009/01.

Only by building industry barriers through centralization and decentralization to cultivate a broad market can we achieve long-term stability.With the increase in the number of patents of each company, the means of patent litigation gradually become invalid.

This not only takes a long time to litigate, but also consumes financial resources.Only relying on Nichia's own arbitrary technology cannot effectively build industry barriers, let alone promote technology and cultivate the market.Therefore, the frustrated Nichia changed its strategy in time in 2002 and began to continuously reach a series of patent cross-licensing agreements with competitors such as Toyoda Gosei, CREE, Philips and Osram to form a patent pool and industrial technology alliance to jointly build barriers. Raise the bar.On the other hand, in the face of the rapidly rising mid-stream and downstream packaging manufacturers, Nichia changed its previous strategy of not authorizing multiple lawsuits, and instead delegated patents and authorized production.Take advantage of other people's production capacity to open up the market.Figure 3-22 shows the current status of Nichia's patent authorization worldwide.The double arrows in the figure refer to the manufacturers cross-licensed with Nichia.The single arrows point to the companies whose patents are directly authorized by Nichia.

Figure 3-22 Authorization between Nichia and major global LED companies

4. The Enlightenment of Sumitomo Chemical, a Loser——The Dictator Does Not Help

Technological dictatorship has gone dark, from leading the industry to disappearing.Previously, Nichia and Sumitomo represented the two mainstream technologies of white LED lighting, gallium nitride and zinc selenide, respectively.The overall technology has its own advantages and disadvantages.Let's first have a general understanding of the two technologies at that time.The current main commercialization approach is derived from Nichia's technology.The gallium nitride chip emits blue light, and the Yttrium Aluminum Garnet (YAG) phosphor is excited by the blue light to emit yellow light.As shown in Figure 3-23, the blue LED chip is installed in a bowl-shaped reflective cavity, covered with a thin layer of resin mixed with yttrium aluminum garnet phosphor powder. Part of the blue light emitted by the LED chip is absorbed by the phosphor, and the other part of the blue light is mixed with the yellow light emitted by the phosphor to obtain white light.The second is the white light LED developed by Japan's Sumitomo Electric, which uses zinc selenide as the material, which is different from Nichia's use of phosphors for color synthesis.In Figure 3-24, the blue light emitted by the thin film layer and the yellow light excited on the substrate are mixed into white light. The basis of LED development lies in blue light technology, and currently Nichia is still leading in blue light LED technology, and Nichia has many patents.But the zinc selenide technology that was once favored by everyone has disappeared. Why?

Figure 3-23 Nichia’s white LED technology

Figure 3-24 Sumitomo Chemical’s white LED technology

Closed technology brings narrow and backward technology.It's a pity that we haven't found any information about Sumitomo's open or cooperative white light technology, and it's hard to find it in LED core interest groups.At present, the luminous efficiency of Sumitomo Technology is lower than that of Nichia Chemical, and most of its current white LEDs are based on Nichia Technology, basically giving up its own lighting technology. In 2003, Boda Optoelectronics was established as a joint venture with Boda Technology, a star in Taiwan's capital market.However, in 2004, it was revealed that Borda used this kind of technology to hollow out its financial statements, and Sumitomo became a tool for it to siphon money in the capital market. It caused a sensation and was called the Taiwan version of the "Enron Incident".The final outcome of Sumitomo's white LED technology turned out to be a scam.

5. Summary

The cases of Nichia Chemical and Sumitomo Chemical enlighten us that the only way to succeed in the lighting industry is to maximize the utility of technology through a balance between centralization and decentralization.No matter how advanced technology is, if you cling to it, you will eventually be eliminated by the market.However, technical ability is the source of entering the rivers and lakes and creating markets.Only with the core technology can we have the ability to maintain the status of the industry by means of centralization and expand the market by means of decentralization.For competitors or companies with complementary capabilities, actively adopt the cooperation method of mutual authorization and franchise authorization, so as to improve their own market response ability, and concentrate resources to develop more advanced technologies, thereby consolidating the technical foundation.At the same time, effectively build industry barriers through strategic alliances to prevent the emergence of new entrants.Finally, with the help of technology openness, one's own technology can get more applications, face more customers, and thus gain a broader market.

A Chinese lighting company that grew out of barbarism.NVC and Opple Lighting are representative and formal Chinese lighting companies.NVC Lighting pioneered the concept of commercial lighting, and Opple Lighting focused on home lighting, especially the development of the ceiling lamp market. Through enclosing market segments, digging sales channels and highlighting brands to distinguish itself from reckless businesses.However, the Chinese lighting companies represented by NVC and Opple are generally born in the chaotic building materials market and OEM production (OEM) of large foreign manufacturers. In the absence of capital and technology, entrepreneurs who have been growing under the pressure of survival and their all The enterprises created will unconsciously choose the business model of short, flat and quick to focus on the market.The technical route is a road with huge investment, slow return and full of risks. The first generation of Chinese entrepreneurs will not try it.However, the general market development ability of Chinese entrepreneurs has made Chinese lighting companies proficient in exploring downstream sales channels. In just a few years, they have occupied a place in the Chinese lighting market.From Figure 3-25, in terms of domestic sales in 2006, NVC and Opple were second only to Philips and even higher than GE.As a result, GE has to rely on NVC's sales channels for its own development in China.

Figure 3-25 Sales of domestic manufacturers in 2006

1. NVC: Outstanding Marketing Channel Features

NVC Lighting was established in December 1998. It was originally an OEM, focusing on the two low-tech market segments of downlights and spotlights. It is so easy to brand its own brand and be familiar to the public. In 1999, NVC pioneered the marketing model of brand stores.What is a brand store?It is a sales facade that gives consumers an on-the-spot experience like a model house. The effect of lamps and lanterns can only be shown with the cooperation of the surrounding environment.Different from other specialty stores full of light bulbs, NVC's brand store is to let consumers experience the consumption experience of lights.In addition, by subsidizing dealers in exchange for control of franchise stores, more dealers are encouraged to participate in opening stores, and the network of NVC brand stores is widely spread.

This form of specialty stores has quickly become a new sales fashion (this also explains why the market is easy to be imitated).In 2002, NVC created a hidden channel, cooperated with designers, and sold its products as a whole through professional designers in the industry.This series of practices are all aimed at building fishnet-style sales points, and the effect of channel expansion can be seen in a relatively short period of time.

NVC focuses on channel development, but most of its production is outsourced. As long as its quality is not inferior to that of its competitors, it can use OEMs of Philips and other major manufacturers in China.Because the lighting industry is an industry with extremely high technical requirements, it is not easy for an enterprise like NVC to make achievements in product technology production.It's better to save resources and take the market path you are familiar with, and do what you can, but the effect is easy to show.

Figure 3-26 Ceiling lamp

2. Opple: Take root in the ceiling lamp market segment

In 1998, Opple began to develop the market segment of ceiling lamps, using ceiling lamps to develop the home lighting market.Before choosing the main ceiling lamp, OP also took some detours.At the beginning of its birth, Opple lingered in the low-end market and fought price wars in the Red Sea.Whatever light is easy to sell in the market, just make the light.However, it is difficult for enterprises to become stronger and bigger if they follow the trend blindly.

"Spring River Plumbing Duck Prophet", Opple, who has been operating the Chinese local market for a long time, found that ceiling lamps are a market segment with great potential in the future, and the giants have left room due to their insensitivity to the market.Figure 3-M is the ceiling lamp that helped Opple make a fortune.The vigorous development of China's real estate market in the new century has brought huge demand to the lighting market. Beijing alone had a demand of more than 300 million yuan a year. At the same time, the profit margin was high and there were no technical barriers. It does fine work to build its own brand and breaks away from the workshop stage.Subsequently, the production scale was expanded, and sales outlets nationwide were widely cultivated.

The successful market segmentation from the downstream has made Opple a leader in China's lighting industry, but the technical bottleneck has always restricted their further development. Judging from the current new product layout and development concept of Opple, it is obvious that they are hovering in the downstream of the industrial chain. stage of confusion.

3. Summary

NVC and Opple Lighting do not have a high-end technical foundation, so it is impossible to talk about the centralization, decentralization and balance of technology, so they cannot go beyond, and they are still hovering in the downstream of the lighting industry chain. Expansion of sales channels is impossible.So can the existing market advantages be transformed into technical strength?This brings us back to the old joke of "market for technology".On this issue, Foshan Lighting introduced high-end technology through cooperation with Osram. Osram became the largest shareholder of Foshan Lighting with 679 million yuan. Osram mainly took a fancy to Foshan Lighting's huge nationwide dealer network. The purpose is to use Foshan as its production base in the Asia-Pacific region.Foshan Lighting expects technical support from Osram.However, since 2005, Foshan Lighting has not received any technology injection from Osram, but has completely become a vassal of others.Therefore, it is difficult to strengthen and make breakthroughs in one's own technology only through cooperation with global lighting giants. After all, you are in the downstream of the industrial chain, while others are in the upper and upper reaches of the industrial chain and occupy a dominant position.Since this way is blocked, is there any successful precedent?Let's take a look at how South Korea's Seoul Semiconductor uses other means to grasp the essence of the industry and make technological breakthroughs.

Figure 3-20 Revenue sources of Philips

Figure 3-21 Principles of three primary colors

Figure 3-22 Authorization between Nichia and major global LED companies

Figure 3-23 Nichia’s white LED technology

Figure 3-24 Sumitomo Chemical’s white LED technology

Figure 3-25 Sales of domestic manufacturers in 2006

Figure 3-26 Ceiling lamp