Chapter 14 Section 2 Maltose and sucrose processing in ancient China

Sugar plays a popular role in improving human nutrition and enriching people's material comforts.Therefore, it has always played an important role in agronomy, food processing and light industry since ancient times.In ancient Chinese medicine, it has always been valued and widely used.

Among the sugars in ancient China, maltose and sucrose were the main ones.The main component of caramel is maltose, which appeared earlier and was brewed from air-dried malt and grains.Because malt contains starch converting enzyme, under its action, the starch in the grain can be hydrolyzed to generate maltose.Its brewing process is very similar to wine making, but to be simple, it can be said that it is the harbinger of human beings using biochemical processes.Of course, sucrose is mainly obtained from sugar cane. Its crystallization and decolorization are both physical and chemical processes, so the production process of white sugar can also be part of the ancient chemical process.Of course, beets are the main raw materials of modern sucrose, but ancient China only knew its leaves and stems as vegetables, and the technology of processing beet sugar was introduced from abroad in the early 20th century.

In addition, honey should also be included in the sugar in ancient China.However, it is collected directly from nature, and the rise of beekeeping seems to be a relatively late event, and there is no chemical process in its processing technology, so it is difficult to be included in the category of ancient chemical technology.

Our ancestors tasted sweet malt sugar probably very early.And it is definitely not the invention of a certain sage, but similar to the invention of wine, it was just a natural occurrence at first.We can imagine that in the primitive society, when people entered the era of farming, more and more grains were harvested, but there were no good storage facilities and places, and there were many chances of being exposed to rain and damp. Then the grain will germinate.If people at that time were reluctant to discard this germinated grain and still used it for cooking, they would find that it became a little sweeter and more delicious.That said, tasted of malt sugar.So people will naturally sum up their experience gradually, optimize the grain buds (called glutinous rice in ancient times), air-dry and grind them into "koji", and use it to saccharify various steamed rice, barley, Yellow rice, sorghum, glutinous rice, corn, etc.After filtering and decocting, the confectionery rich in maltose will be obtained.This kind of confectionery was originally called "饧" or "Yi".The word "饧" was originally pronounced as "Tang", but it was changed to "Yang" in the Han Dynasty. Later, the sound of "饧" was changed from Tang, and it was written as sugar, or from rice as sugar, which became the current word for sugar.In addition to maltose, there is another ingredient in glutinous rice and glutinous rice syrup called dextrin. In modern chemistry, dextrin is also a sugar, but it has no sweet taste.

It can be inferred from various texts about glutinous rice, that the processing and production technology of glutinous rice appeared in the Zhou Dynasty about 3000 years ago, and even in the Yin Dynasty.For example, in the "Book of Books" written during the Warring States Period, also known as "Shangshu", there is already a saying "farming for sweetness", which means that the cultivated and harvested grains can be used to produce sweet (sweet) glutinous rice.

By the Han Dynasty, it was common for people to eat maltose products.At that time, there were hawkers playing the flute along the street and selling malt glutinous rice, and malt gluten had become a snack for common people.

Written records about the production process of glutinous rice cakes appeared later.The earliest mention of this matter was probably "Si Min Yue Ling" written by Cui Shi (shi Shi) in the Eastern Han Dynasty, but it was very simple: "Frozen first in October, made cold rice, and boiled glutinous rice." "Liang 饧" is a kind of thicker 饧; the so-called "Bao Yi" is a "thin yee" with a shorter cooking time and a lower degree of concentration."Qi Min Yao Shu" written by Jia Sixie, an agronomist in the late Wei Dynasty, detailedly introduced the methods of making saccharified glutinous rice and many "boiled glutinous rice dumplings" at that time.The technique of processing glutinous rice dumpling is very easy to understand. He said: "making glutinous rice dumpling in mid-August. Soak the wheat in the basin, pour out the water, and expose it every day. Once in the water, remove it. The feet are born ( Refers to the young roots that grow out of the wheat seeds when they germinate), spread the wheat on the mat, about two inches thick. Wash it with water once a day, the buds will stop when they grow, and then they will be collected and dried. Do not make cakes, and the cakes will not be formed Re-appointment. This is to cook white glutinous glutinous rice. If you cook black glutinous rice glutinous rice, wait for the buds to grow green and form cakes, then use a knife to cut them apart and dry them. If you want the glutinous glutinous rice to look like amber, use barley as glutinous rice .” The method of making white sugar introduced in the book is: use the dried white young wheat sprouts.The large iron pot for boiling sugar must be polished and clean, otherwise there will be an oily smell.A jar with the bottom cut off was erected on the pot, and the jar was built on the big iron pot along the bottom mud to prevent the syrup from overflowing due to boiling.One stone of rice can be saccharified for every five liters of dry malt.First wash the rice and cook it into rice, then spread it out and let it warm up, then put it in a large basin and mix it with the malt powder evenly.Then they are sealed in an urn with a hole in the bottom (plugged first), covered with a quilt, and kept at a relatively high temperature to saccharify.The rice in the urn should remain fluffy.After one day in winter and half a day in summer, the rice turns into gruel, and the saccharification is completed.Add hot water, pull out the plug at the bottom of the urn, release the sugar solution, and boil it in an iron pan over a warm fire.Stir constantly so that it does not burn.According to experience, until it is thickened, stop the fire, and it will become hard when it cools down.The glutinous rice made from sorghum rice and millet is as white as ice crystals.

Since then, the raw materials for the creation of Yee Gu have become more and more extensive, and the methods have been adjusted continuously, but there has been no substantial improvement.However, the varieties of confectionery made with maltose are constantly being refurbished, such as the Northeast specialty "Kanto sugar" in later generations, "tanggua" for the stove on the 23rd of the twelfth lunar month, some "sesame Nantang" in the south, and "a nest of sweets" from the south. The halva developed from "Silk" (see "Tiangong Kaiwu·Ganxi") are all famous and special caramel snacks centered on maltose.For example, "Yiwosi" is a thick maltose that is repeatedly beaten, stretched, and folded with a wooden stick to fill it with tiny air bubbles, so this kind of sugar is both sweet and crisp.

Throughout the ages, sugar cane has always been the most important raw material for sugar production. It has high sucrose content, simple sugar production process and good product quality.

In the Western Han Dynasty, it was known that most of the water in the cane juice was driven off by the method of sun exposure and warm fire (heating to 70 or 80 degrees), or a combination of the two, that is, "boiling and exposing" to obtain thickened sugarcane juice. Thick, gelatinous syrups, in which most microbes are also killed, can be stored for longer periods of time.This kind of syrup is called cane maltose or cane glutinous rice.

With the improvement of the technology of decocting cane juice, the water in it can be fully evaporated without burning.When the moisture content drops below 10%, it will solidify into sugar cubes after cooling, and the color is reddish brown, so it is called "stone honey", but it is not yet crystallized sugar. "Hanshu Nanzhong Eight Commanderies" has already mentioned that this kind of sugar is produced in the Jiaozhi area (now northern Vietnam).

During the Tang Dynasty, my country's sucrose technology made great progress, and today's red granulated sugar began to appear at that time.But it should be said realistically that this granulated sugar technology was produced by drawing on the advanced sugar production experience in India at that time.At that time, there were at least three advanced experiences in India's granulated sugar method: First, cane pulp was treated with lime or plant ash before crystallization.According to modern scientific sugar production principles, this measure is very important to the crystallization and yield of sucrose, because in addition to sucrose and water, there are some organic acids that are not very large in content but extremely unfavorable to sucrose crystallization. Components, they will promote the hydrolysis of sucrose to produce reducing sugars (such as glucose, fructose, etc.), this kind of sugar not only cannot crystallize itself, but also generates molasses (called "sugar oil" in ancient my country) to hinder the crystallization of sucrose, so It is necessary to use "ash" to neutralize or precipitate those free acids; and it can also precipitate some organic non-sugar, inorganic salt, and sediment suspensions, which can not only improve the taste of cane juice, but also make the cane The viscosity of the juice decreases and the color becomes brighter, which is also beneficial to the precipitation and quality of sucrose.Second, Indian sugar technicians know how to pay attention to the selection of sugarcane varieties. According to their experience, seedlings longer than eight feet are not suitable for boiling sugar, while those with short stems of six or seven feet are good varieties for sugar production.Later, our country learned from this experience of India.Third, the Indian sugar industry has taken measures to separate molasses, which is very conducive to the crystallization of sugar.

Another major achievement in the sugar making process in the Tang Dynasty of our country was mastering the skill of making large crystal rock sugar.However, in the Tang and Song dynasties, people called rock sugar "icing sugar". It was not until the white granulated sugar came out in the Ming Dynasty that people also called white granulated sugar "icing sugar".Regarding rock sugar, our country started to manufacture it probably from the Suining area of the Fujiang River Basin in Sichuan.Legend has it that during the Dali period of the Tang Dynasty (AD 766-779), a monk named Zou came to Suining Umbrella (Umbrella) Mountain to teach this skill.Since then, rock sugar has developed rapidly. In the Song Dynasty, there were Futang (Fuzhou) in Fujian, Siming (Ningbo) in Zhejiang, Panyu in Guangdong, and Guanghan (now the Baishui Basin at the junction of Sichuan and Gansu provinces). Suining is the crown.Regarding the origin, technology, nature and storage method of rock sugar in Suining area, the book "Sweet Sugar Spectrum" (Figure 4-6) written by Wang Zhuo, a native of Suining in the Southern Song Dynasty, has detailed records.According to his records, the scene of making rock sugar at that time was roughly: boil cane juice (selected purple and tender Du cane) until it was as thick as glutinous rice during the cold weather in the first month of the lunar calendar.Insert the bamboo strips into the urn first, then fill it with cane pulp and cover it with a bamboo mat.Two days later, sugar crystals like fine sand precipitated on the liquid surface.After the fifteenth day of the first lunar month, they "form into small pieces or embroider bamboo shoots like millet ears, and gradually increase in size like beans", or "become a seat like a mountain".Until May, when spring grows and summer grows, the crystals will no longer grow. At this time, the remaining sugar water should be poured out in time, and the rock sugar should be dried until it becomes hard.Remove the crystals on the bamboo strips and the walls of the kettle.Because rock sugar is very afraid of dampness, the storage is very particular: first spread a layer of large (or small) wheat chaff on the bottom of a large urn, put a bamboo basket on it, and put a layer of bamboo shoots on the bottom of the basket. Then put in rock sugar, and finally cover the urn with a bamboo mat.This kind of rock sugar is purple in color, followed by dark amber and yellow.It was very popular in the Tang and Song Dynasties, and it was a good gift from relatives and friends.Su Dongpo once wrote a poem saying: "Fujiang and Zhongling share the same taste of water. I recommend amber on the ice plate, which is as beautiful as icing sugar." In the Ming Dynasty, my country had decolorized white sugar.So I made rock sugar with white granulated sugar, and the result is the white crystal sugar we see now.

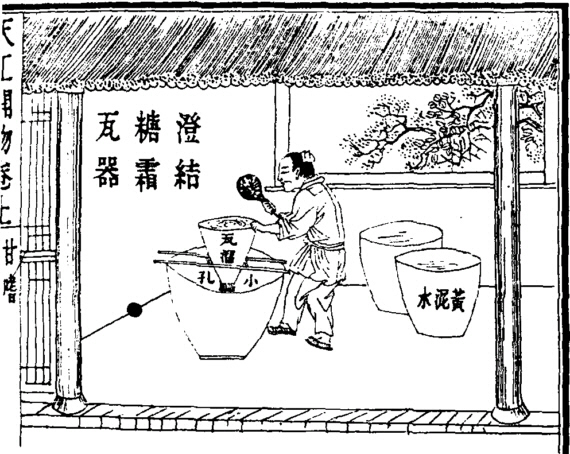

Figure 4-6 "Sugar Frosting Spectrum" written by Song Wangzhuo

To produce white sugar, cane pulp must be decolorized before crystallization.During the Yuan and Ming Dynasties, sugar workers in my country started this research and achieved success.The earliest attempts seem to be coagulation clarification using duck egg whites.This method is to add a little whipped duck egg white to the sugarcane juice, and then heat it. At this time, the coloring substances and dregs in it will condense with the egg white, float to the liquid surface, and then skim off to make the sugarcane juice The juice becomes clear and the tan color fades.But decolorization with this method is not thorough after all, and uneconomical.Later, this method was probably only used when making rock sugar.

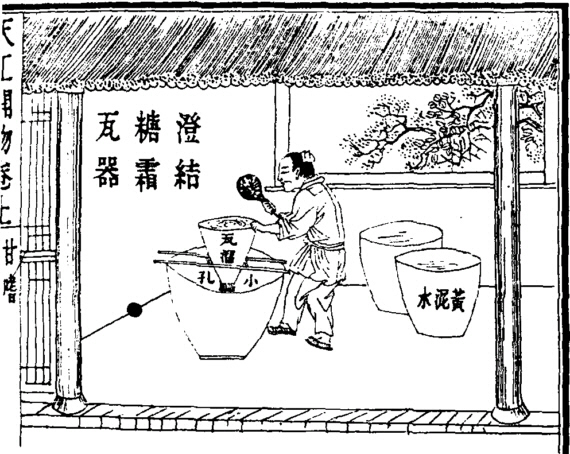

Among the decolorization techniques of ancient granulated sugar in our country, the yellow mud decolorization method has the greatest achievement and the widest influence.The development of this technology can be roughly divided into two stages from accidental discovery to conscious application and improvement.The first stage is the mud-covering method. During the operation, the cane juice is first heated and evaporated, concentrated to a viscous state, and then poured into a funnel-shaped earthen bowl (called "waliu"), and the bottom is sealed with straw in advance. mouth.After two or three days, the lower part of the bowl was clogged with crystallized sugar.Put the clay bowl on the urn or pot, and press the yellow mud cake evenly on the top of the syrup.At this time, the yellow mud will gradually and partially infiltrate into the syrup, absorb various colored substances in it and slowly sink to the bottom of the bowl, then pull out the plug grass, and the mud will drop into the urn below along with the molasses. in the pot.In this way, after a long period of time, the decolorization is completed, and the adobe is removed. At this time, the upper part of the bowl becomes fine white sugar, and the bottom part of the clay bowl is still dark brown sugar.According to legend, the invention of this technique was very accidental.The "Quanzhou Fu Zhi" written by Huai Yinbu and Chen Shi of the Qing Dynasty said: It is said that in the Yuan Dynasty, there was a sugar craftsman surnamed Huang in Nan'an County, Quanzhou Prefecture. Syrup on top.When cleaning later, when the clods were removed, the sugar crystallized in the upper layer of the tank became very white.So later generations followed suit.This mud-covering method was imitated continuously by later generations, and the sugar craftsmen gradually realized that the yellow mud has the ability to decolorize, so they improved the mud-covering method and evolved the method of adding yellow mud to the syrup. This is the mud decolorization method. The second stage of development.This improvement not only makes the decolorization effect better, but also greatly improves the efficiency of sugar decolorization.Figure 4-7 is a description of this yellow mud decolorization method, which is an illustration attached to "Tiangongkaiwu·Ganji".

In the modern sugar industry, in addition to sugar cane, sugar beet is also an important raw material. After the 20th century, it was widely planted in Western Europe, Germany and France, and beet sugar was produced in large quantities.At present, the sugar content in the beet tubers of good varieties can reach more than 20%.In ancient my country, sugar beet has been planted and used, but its fat leaves are mainly eaten; its leaves and seeds are often used as medicine.But probably few are aware of eating its sugary roots.In ancient my country, beet had many names, such as 菾菜, beet, 莙荙荙, and chard.my country introduced sugar beet as a raw material for sugar production around the beginning of this century. In 1901, some Russian Poles first tried planting it in the Heilongjiang River Basin; , This is the beginning of industrialized production of beet sugar in our country.And small workshop production may be earlier.

Figure 4-7 White granulated sugar produced by mud decolorization method (taken from Xi Yongxuan's version of "Tiangong Kaiwu")

Figure 4-6 "Sugar Frosting Spectrum" written by Song Wangzhuo

Figure 4-7 White granulated sugar produced by mud decolorization method (taken from Xi Yongxuan's version of "Tiangong Kaiwu")